The four-wire resistive touch screen presses the touch screen with a finger or a hard object, causing its resistance to change so that the display starts to work. Then, it is very important to detect whether the touch layer is effective before the product is completed. This article introduces the detection method of touch occurrence on a four-wire resistive display.

All touch screens can detect when a touch occurs by using a weak pull-up resistor to pull one layer up and a strong pull-down resistor to pull the other layer down. If the measured voltage of the pull-up layer is greater than a certain logic threshold, it indicates that there is no touch, and vice versa. The problem with this approach is that the touch screen is a huge capacitor, and you may also need to increase the capacitance of the touch screen leads to filter out the noise introduced by the LCD. A weak pull-up resistor connected to a large capacitor will increase the rise time and may cause spurious touches to be detected.

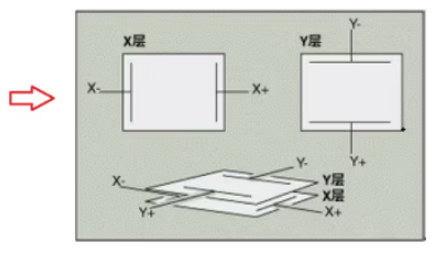

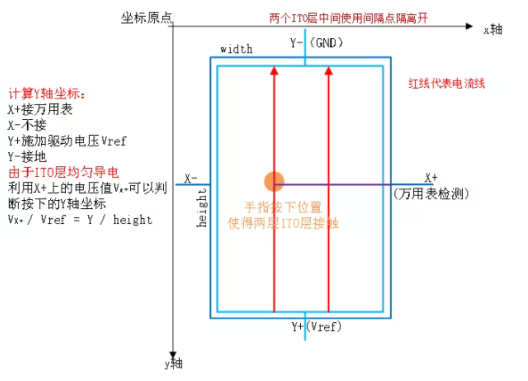

The four-wire touch screen includes two resistive layers, the ITO layer we talked about earlier. One layer has a vertical bus on the left and right edges of the screen, and the other layer has a horizontal bus on the bottom and top of the screen. As shown below.

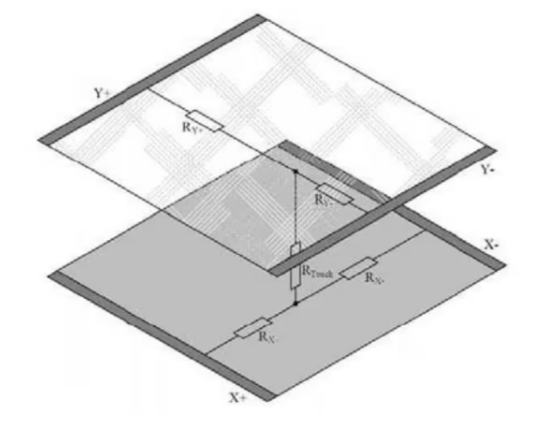

The resistances in the X layer and Y layer are evenly distributed, forming a uniform electric field, which is equivalent to the following figure

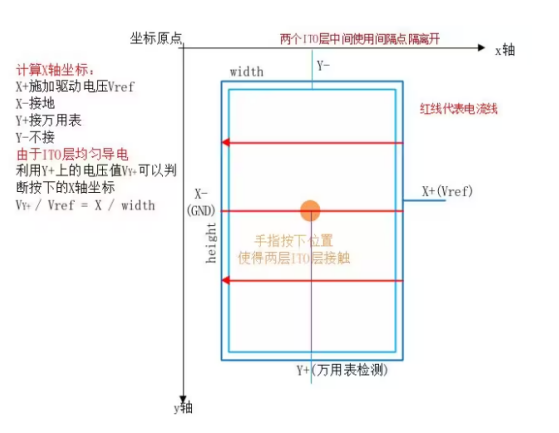

Therefore, to determine whether a touch occurred and where it occurred, we need to calculate the XY coordinate position. The specific calculation method is divided into two steps:

1. Calculate the X-axis coordinate position

Step 2, calculate the Y-axis coordinate position

The measured voltage is usually converted into a digital signal by the ADC. This is what the touch chip needs to do. After simple processing, it can be used as coordinates to determine the actual position of the contact.

Search

Search